In the food processing industry, selecting the right conveyor system is critical for improving production efficiency, reducing maintenance costs, and ensuring product quality. However, many companies often overlook thorough testing of material characteristics during the equipment procurement process, resulting in mismatched equipment that can negatively affect overall production line performance.

The Importance of Material Testing

Every material has unique flow properties, moisture content, density, and particle characteristics, which directly impact conveyor selection and performance. Conducting comprehensive laboratory testing of materials before procurement provides companies with key insights:

- Flow Characteristics: Understand how materials behave under different conditions, including angle, moisture, and density, helping to select the most suitable conveying method.

- Breakage and Wear Potential: Assess the likelihood of material breakage or wear during conveying, guiding the choice of durable equipment.

- Cleaning and Maintenance Requirements: Determine the equipment cleaning and maintenance needs for the material, ensuring long-term stable operation.

- Equipment Sizing and Configuration: Accurately calculate the required equipment size and configuration based on material properties to avoid over- or under-design.

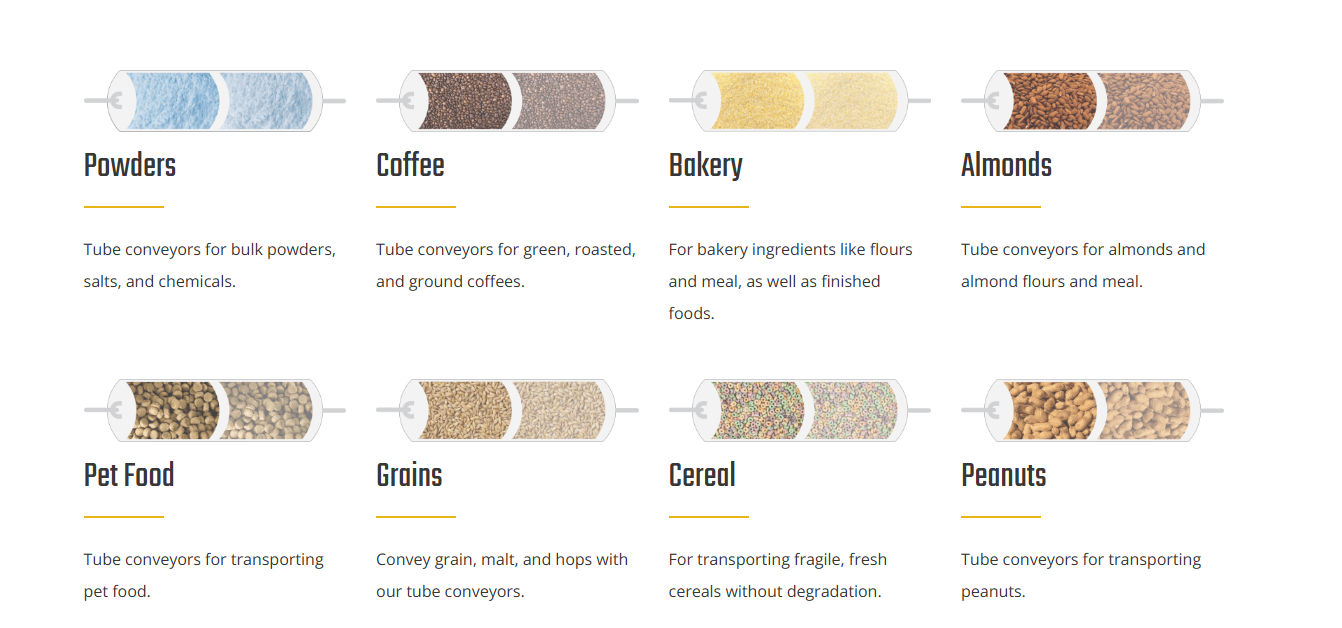

Choosing the Right Conveyor System

Different material properties require different types of conveyor systems. For example, materials with high moisture content or fragility may need flexible conveyor systems to minimize material loss and equipment wear. For high-density or high-temperature materials, conveyors that can handle heavy loads or high temperatures are necessary.

By performing professional material testing, companies gain detailed data on material behavior, guiding the selection and optimization of the conveyor system. Early testing not only improves production efficiency but also reduces equipment failure rates and extends service life.

Conclusion

Before investing in a new conveyor system, conducting comprehensive material testing is a critical step to ensure system performance and production efficiency. By understanding material characteristics, companies can select the most suitable conveyor equipment and avoid production issues caused by mismatched systems. This proactive approach not only enhances productivity but also lowers operational costs and strengthens overall competitiveness.